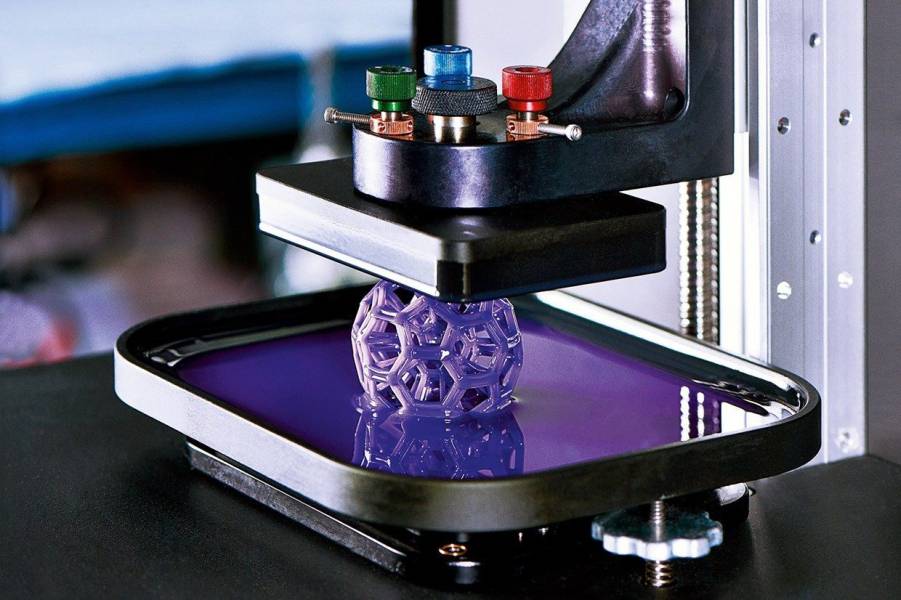

3D printing is a technology that has been around for decades but is just now gaining in popularity for manufacturing many different products for medical use, automotive, and even electronics. This article will discuss some of the more common materials used in 3D printing and why they are useful for manufacturers.

Composites

A composite is a material that contains two or more different materials. These can be combined to make stronger parts, or they can be used on their own with different properties. Composites are often used in 3D printing because they offer several benefits over other types of materials. They allow the designer to create complex structures with many different load paths. The resulting part has better mechanical properties than those made from only one material. Additionally, when deciding between Formlabs vs Nexa3D, manufacturers often consider what materials the 3D technology can handle.

Rubber

Rubber is a versatile material that can be used in a variety of applications, including tires, shoe soles and other footwear, sports equipment, and even your smartphone case. Rubber 3D printing materials are typically made from either natural or synthetic rubber compounds.

Thermoplastics

Thermoplastics are a type of plastic material that can be melted and then cooled down to become a solid again. Thermoplastics – including the KYDEX® T thermoplastic sheet – are often used in 3D printing because they’re strong enough to hold up under pressure from the printer extrusion nozzle but still flexible enough that they won’t break when they’re printed. These materials are also used in the automotive and aerospace industries, as well as other applications where it’s important to print parts that can withstand high temperatures without warping or cracking.

Most thermoplastics are also recyclable. This means that if you have any leftover from a project you can take them to a recycling center.

Gold, Silver, and Bronze

It should go without saying, but anything you can melt could be a good material for 3D printing. It’s true that gold, silver, and bronze are used in jewelry. Gold is a soft metal and is one of the most malleable and ductile metals found on earth, which means it is easy to work with when shaping or forming into different designs. Silver is also a soft metal though it has slightly more resistance to being shaped than gold does.

Stainless Steel

Stainless steel is a good choice for 3D printing because it’s strong, durable, and corrosion-resistant. It’s also versatile, making it suitable for jewelry, medical devices, and high-performance parts. 3D printing is also being explored for making buildings. Because the parts can be formed into a sturdy structure, this means that some steel buildings could be created on-site if the right materials and technology were available. This can lower transport costs and more.

Titanium

Titanium is a metal that is used in many medical devices, sports equipment, and aircraft. It’s very strong, but also light. The downside of titanium is that it’s expensive compared to other metals like aluminum. Because it is relatively neutral as a metal, and it’s very strong, it’s often used in hip and joint prosthetics because these locations get a lot of pressure put on them regularly.

Carbon Fiber

Carbon fiber is a strong and lightweight material that has been used throughout the aerospace supply chain and in the automotive industry for years. Its high strength-to-weight ratio makes it ideal for creating parts with high strength and low weight, which are particularly useful in aerospace applications like aircraft or spacecraft. It can also add stability to other materials like plastics to make them stronger and sturdier.

Food

Did you know that you can 3D print food? You can 3D print food that looks like other foods. You can also 3D print fun candies and even pizza. It uses real ingredients, but the process by which it’s made is automated so that it reduces the cost and time to make.

Conclusion

The future of 3D printing is bright, and the materials being used are only going to get better and more advanced. With 3D print technology being adopted in more industries, it’s hard to guess what will be possible in just a few years. With these materials alone, some creativity, and some ingenuity, it may be that people will go to the store in the future to have things 3D printed on-site to take home instead of lots of large items being shipped all over.

HedgeThink.com is the fund industry’s leading news, research and analysis source for individual and institutional accredited investors and professionals