Diesel engines have played a critical role in commercial, industrial, and recreational vehicles due to their durability, efficiency, and adaptability. While many engines come and go, certain platforms have proven remarkably enduring over decades of use. Their longevity results from a combination of robust engineering, practical design, and continuous refinement based on real-world feedback.

The diesel industry has faced pressure to balance performance, emissions standards, and reliability, often requiring innovative approaches to engine design. Platforms that successfully navigated these challenges have earned reputations for resilience and dependability. Understanding why certain diesel engines endure offers valuable insight for fleet managers, mechanics, and enthusiasts.

Engineering for Longevity

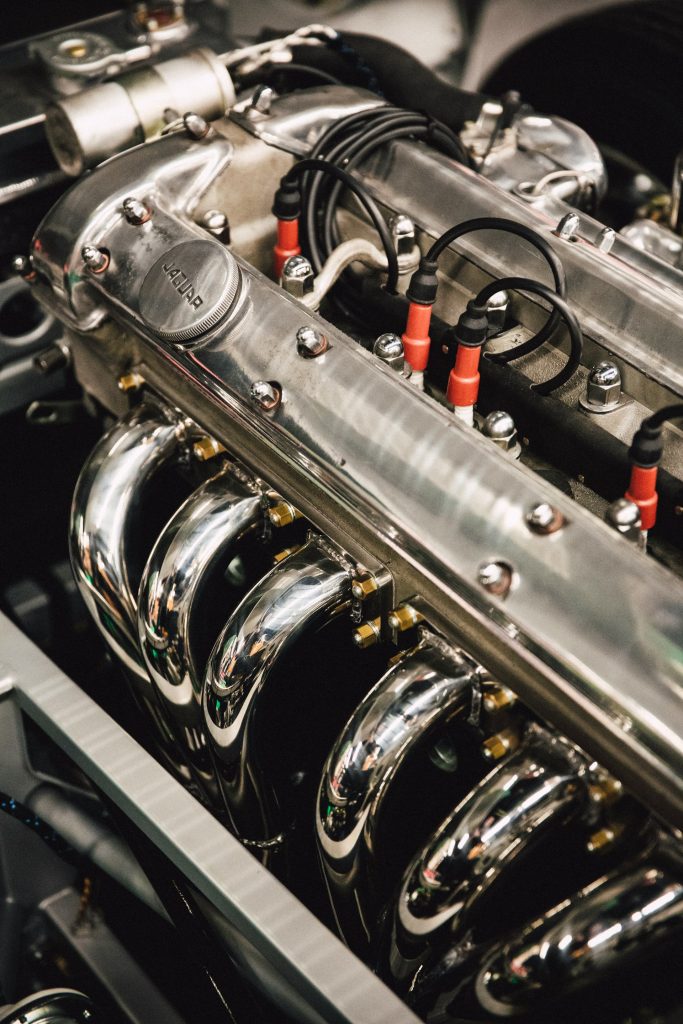

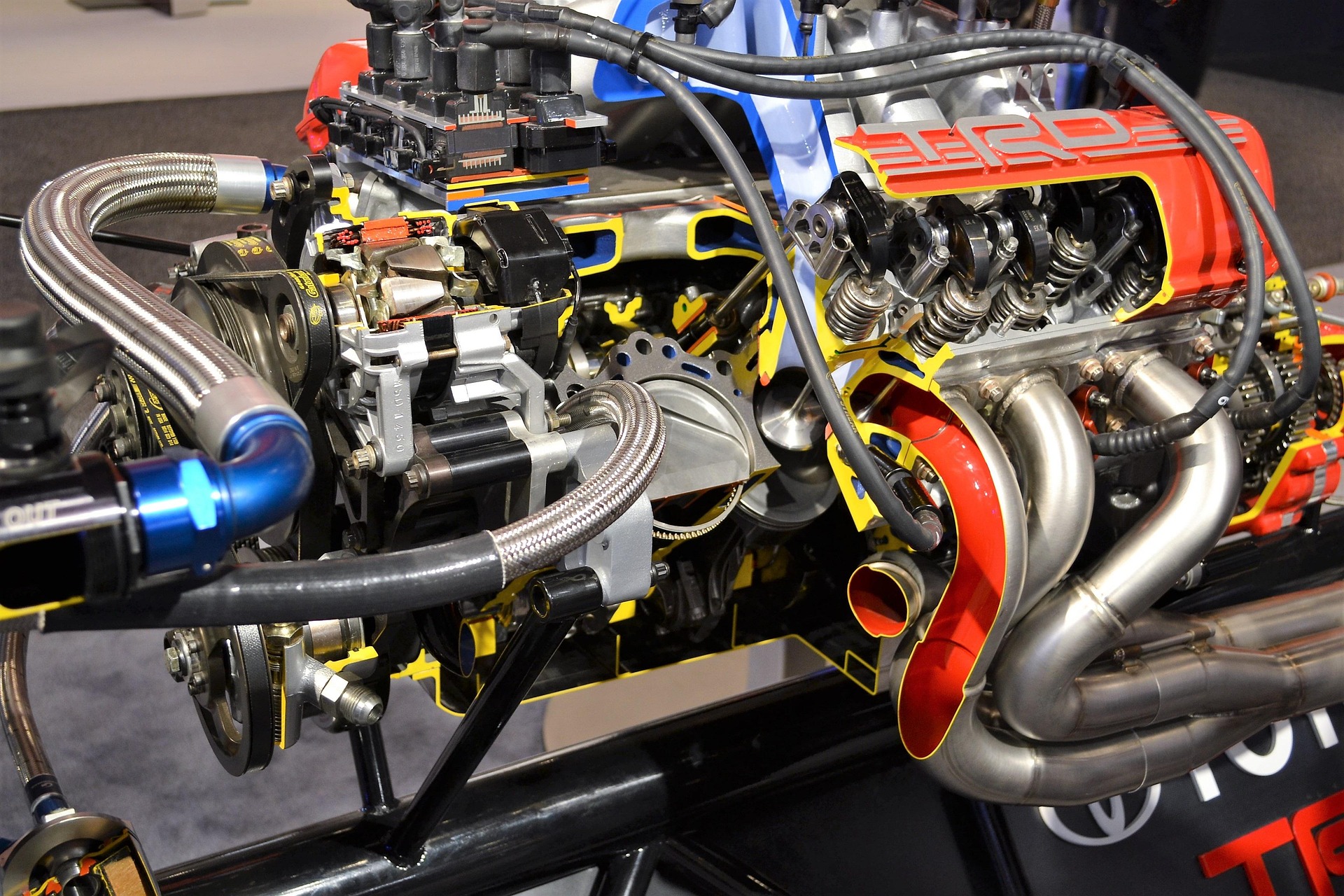

Robust engineering underpins the endurance of diesel platforms, with materials, tolerances, and design choices all contributing to reliability. High-strength components, reinforced blocks, and precision machining minimize wear and failure. Engineers prioritize simplicity in critical systems to reduce the likelihood of malfunctions under heavy use.

The balance between performance and durability is key; over-engineered engines can be unnecessarily heavy, while under-engineered designs fail prematurely. Successful platforms have achieved an equilibrium, offering adequate power without compromising structural integrity. This careful engineering creates engines that remain functional for hundreds of thousands of miles.

Maintenance accessibility is another critical factor. Engines that allow routine inspections, easy replacement of wear parts, and standardized components tend to last longer. Reduced downtime and straightforward repairs increase operational efficiency and fleet longevity.

Proven Performance in the Field

Real-world testing distinguishes engines that endure from those that falter. Engines must perform reliably across varying climates, altitudes, and load conditions.

Consistent field performance builds confidence among operators and reinforces platform credibility. If you explore Cummins ISC 8.3L engines, you’ll see that these engines have earned a reputation for reliability, powering trucks, buses, and industrial machinery for hundreds of thousands of miles with minimal issues. The combination of durable components, predictable power delivery, and ease of maintenance makes them a preferred choice for fleets and operators who require long-term dependability.

Fleet managers emphasize engines that maintain efficiency while tolerating heavy-duty cycles. Platforms with proven endurance reduce unplanned service interruptions and increase productivity. Dependable performance in diverse conditions contributes to long-term adoption and platform longevity.

Simplicity and Serviceability

Engines that prioritize simplicity tend to endure because they reduce the potential for failure and allow easier servicing. Complex systems, while capable, can create more points of vulnerability. By contrast, engines designed with accessible components, clear service procedures, and standardized parts tend to last longer.

Maintenance-friendly platforms encourage operators to perform routine inspections, oil changes, and part replacements on schedule. Reduced service complexity lowers downtime and operational costs. User-friendly design benefits both small operators and large fleet managers alike.

Design features promoting serviceability:

- Modular engine components for straightforward replacement

- Accessible filters, pumps, and belts

- Standardized fasteners and parts for interchangeability

- Clear service manuals and diagnostic tools

- Fuel and lubrication systems designed for minimal downtime

Adaptation and Evolution

Enduring diesel platforms often change to meet changing regulations and performance demands. Emissions standards, fuel efficiency requirements, and technological advancements necessitate incremental updates. Engines that adapt while retaining core reliability continue to thrive in the market.

Manufacturers that refine combustion systems, electronic controls, and auxiliary components without overcomplicating the platform achieve long-term success. Incremental upgrades maintain operator familiarity while ensuring compliance with modern standards. Adaptable platforms retain relevance and maintain their reputation for endurance.

Support from aftermarket and parts suppliers further reinforces longevity. Ready availability of replacement parts and technical support encourages continued operation. Operators can maintain engines for decades without needing complete replacements.

Fuel Efficiency and Reliability Balance

Enduring diesel engines combine dependable performance with reasonable fuel efficiency. Fuel systems that maximize combustion effectiveness without overstressing components strike an ideal balance. Engines that are too aggressive may deliver higher power but sacrifice long-term reliability.

Operators prioritize platforms that minimize downtime and fuel costs over theoretical peak performance. Real-world reliability often outweighs incremental efficiency gains that come at the expense of engine life. Platforms that meet operational needs efficiently maintain widespread adoption and loyalty among users.

Designing for predictable consumption and durability ensures engines remain economical over their service life. Standardized fuel delivery systems and proven injector designs contribute to consistent performance. Endurance emerges from the synergy between engineering, maintenance, and operational practices.

Cooling and Thermal Management

Effective cooling and thermal management are crucial for diesel longevity. Engines subjected to excessive heat experience accelerated wear, reduced component life, and increased failure risk. Reliable cooling systems allow engines to maintain consistent performance even under heavy load or extreme conditions.

Design features like oversized radiators, high-flow water pumps, and well-placed oil coolers mitigate thermal stress. Materials chosen for heat resistance further enhance reliability. Proper cooling supports operational consistency.

Operators must also manage ambient conditions, airflow, and routine coolant maintenance. Neglecting thermal considerations can shorten lifespan dramatically. Long-lasting diesel platforms incorporate both engineered solutions and user-friendly maintenance requirements.

Operator Practices and Maintenance Culture

Even the most durable engines rely on disciplined operator practices and maintenance culture. Timely oil changes, filter replacements, and scheduled inspections prevent small issues from escalating into major failures. Experienced operators understand that attentive care directly correlates with engine longevity.

Fleet managers encourage routine checks, proper load management, and adherence to service schedules. Documentation, monitoring, and feedback loops reinforce best practices. Engines that are well-maintained in real-world conditions often outperform newer but neglected alternatives.

Operator habits contributing to longevity:

- Scheduled oil and filter changes according to manufacturer guidelines

- Monitoring engine temperature and fluid levels daily

- Avoiding overloading beyond rated capacity

- Using high-quality fuels and lubricants consistently

- Periodic inspection of belts, hoses, and turbo systems

- Immediate attention to unusual noises or warning signals

- Documentation of maintenance activities for fleet management

Aftermarket Support and Parts Availability

Ready availability of replacement components, diagnostic tools, and technical support allows operators to maintain engines efficiently without costly downtime. Access to quality parts ensures that routine maintenance and unexpected repairs can be performed promptly, preserving engine performance over decades.

Strong partnerships between manufacturers and aftermarket suppliers enhance reliability and support fleet operators. Training programs, repair guides, and certified service centers provide guidance and expertise for complex issues.

Proactive engagement with aftermarket resources allows fleets to plan maintenance, source hard-to-find parts, and implement upgrades without disruption. This strategic approach reduces the total cost of ownership and maximizes operational uptime. Long-lasting diesel platforms leverage both engineering excellence and accessible support to sustain performance in real-world conditions.

Certain diesel platforms endure due to the combination of robust engineering, proven performance, and operator diligence. Engines demonstrate the value of balancing simplicity, adaptability, and reliability. By prioritizing maintainability, thermal management, and predictable performance, these platforms maintain relevance for decades.

Adaptation to evolving regulations, fuel efficiency demands, and operational needs ensures that reliable engines continue to serve modern fleets. Supportive aftermarket ecosystems, accessible service protocols, and trained operators further extend platform lifespan. Long-term success in diesel platforms emerges from thoughtful design, consistent maintenance, and practical real-world performance.

A dad of 3 kids and a keen writer covering a range of topics such as Internet marketing, SEO and more! When not writing, he’s found behind a drum kit.