A consistent problem in CNC machining is to form real internal right angles, because rotary cutting tools such as end mills have round geometry. Natural crevices occur in the corners using these tools, so sharp 90-degree turning is almost impossible.

This is a problem when it comes to precision applications like molds, enclosures and aerospace components where mass to be molded has internal corners that are intended to be sharp. The difference between CAD intent and machining reality can enable higher setup times, short tool life, and part rejection.

To address this, higher quality contemporary manufacturers employ hybrid workstreams, optimized toolpaths, and digital simulations to achieve functional precision. Companies like WayKen manufacturing are at the forefront of this challenge, leveraging design foresight and precision techniques to improve machining internal right angles with accuracy and consistency.

Geometric Limitations in Internal Corner Formation

At the core of the issue in machining internal right angles is tool geometry. The most common cutting tools, end mills, are rotary and have circular profiles that cause an inevitable tool radius. In making a cut on a 90-degree corner, this geometry produces a rounded profile or what is called a corner fillet, instead of an absolutely square corner. This small radius may interfere and avoid the assembly process, especially when the mating part has sharp corners.

The dimensions increase the complexity when cavities are deep or pockets narrow. Access to tools is restricted and long-reach tools bend easily under load when cutting. It may result in unsatisfactory surface finish, dimensional accuracy, or even tool breakage.

Also, materials like titanium or engineering-grade thermoplastics, such as PEEK, impose more thermal and mechanical stresses during an internal cut. Extraction of stock in these narrow areas without deforming the workpiece can only be achieved by balancing the rigidity of the tool, spindle speed and feed rate, and the depth of cut, as only strong CAM systems and experienced operators can orchestrate.

Design-Compatible Alternatives and Corner Relief Strategies

A common solution to this in machining internal right angles is introduction of “dog-bone” or “T-slot” fillets. They are long relief put in to internal corners so that parts having sharp outside corners, can nest together accurately. Although these may look visually unorthodox, such design adjustment works well to achieve a fit but much easier to machine with standard end mills. They also eliminate using cutters that are too small or using EDM and decrease cycle time and tool life.

The second elaborated process is application of Electrical Discharge Machining (EDM), in specific the wire EDM. As opposed to rotary machining, EDM cuts working with the loss of the material by means of controlled electrical discharge. This allows erection of exact interior angles and minimum radii. The price to pay though is in speed and cost of the process. EDM is normally used on low runs, tooling inserts or where there is an extremely tight tolerance and geometric accuracy is of paramount concern.

High-Precision Tooling and CAM Strategy Integration

With advanced Computer-Aided Manufacturing (CAM), engineers have the option to modify the toolpaths according to the corner geometries and material characteristics. When dealing with corners the rest machining strategies are especially convenient. Secondary finishing passes by smaller diameter tools are used to minimize the radius and fine the geometry after a first roughing pass. Not only does this reduce tool building up, but it also means the tool load will be spread more regularly throughout the operation.

Micro-grain carbide end mills, long-neck or necked-down end milling are also used to reach corner recesses and still offer rigidity. When utilized at low radial engagement and high spindle speeds, these will be able to finely machine internal features at low risk of chatter. Trochoidal and peel milling curves in the toolpath are adaptive mechanisms to help dissipate heat and ensure steady tool engagement.

There is a layer of flexibility brought by five-axis machining. When corners are approached at an indirect angle by tilting the workpiece or tool, then remaining material and internal radii are minimized. This does not completely get rid of the problem but it presents a useful alternative in high-complexity part geometries. When synergized with dynamic work offsetting and high-resolution feedback systems, the overall outcome is more fidelity in internal features.

Integrated Engineering Solutions for Right Angle Challenges

The best way to correct the problems with machining internal right angles would be to stop correcting them as reactive corrections and instead start planning the manufacturing process ahead in a design-aware fashion. The engineering today works hand in hand at the design stage with the machinists to find out the features that will significantly impair clean machining. It is typical to insert deliberate fillets or corner clearances into the CAD part even prior to generation of the toolpath.

Digital simulations and Finite Element Analysis (FEA) allow predicting stress concentration around internally-housed features, which can be used to determine whether sharp edges would be required, structurally, or whether a slight radius would permit greater structural endurance. In many cases, machining limitations are used to make design changes that enhance manufacturability as well as mechanical operation. An example is that in high-load applications, rounding internal corners to the tool radius can allow minimizing stress risers and fatigue life of the part.

The addition of in-process monitoring sensors is another great development. They are sensors in terms of detecting spindle load, vibration and acoustic emissions in real-time in manipulators to detect anomalies during corner machining. Information in such systems may bring about toolpath corrections or halt processes to avoid damages. Machine learning algorithms take this ability one step further, using past performance data to improve how tools are chosen and implemented to improve performance of future parts.

Advanced Manufacturing Integration: Data-Driven Internal Geometry

Instead of viewing internal corners as individual problems, several manufacturers have incorporated them as a systems-level limitation. More sophisticated CNC processes incorporate DFM consultation, material response study, and smart program generation to develop individualized solutions. Machining strategies are also varied not according to rigid templates but rather based on material machinability, geometry, and part function.

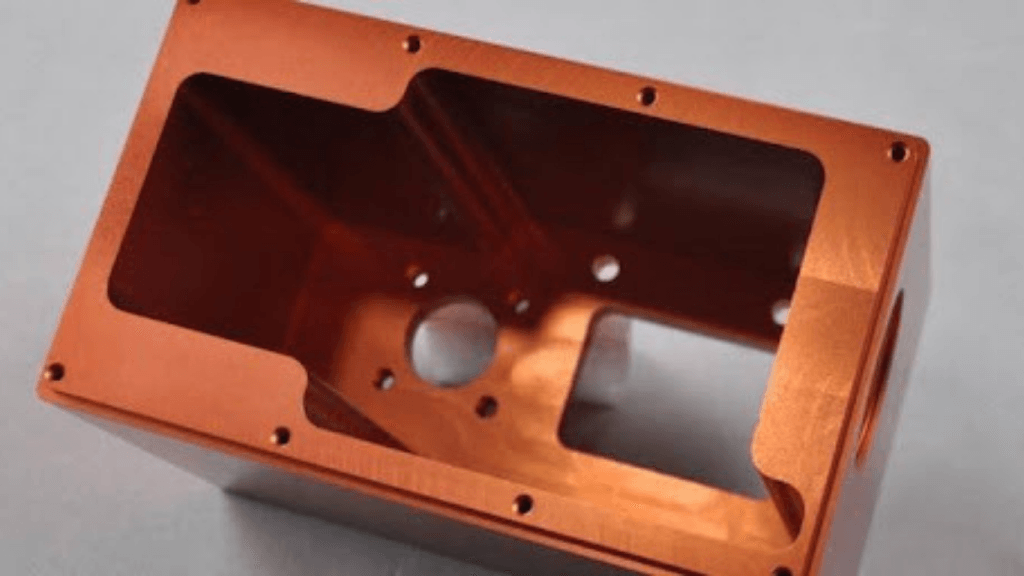

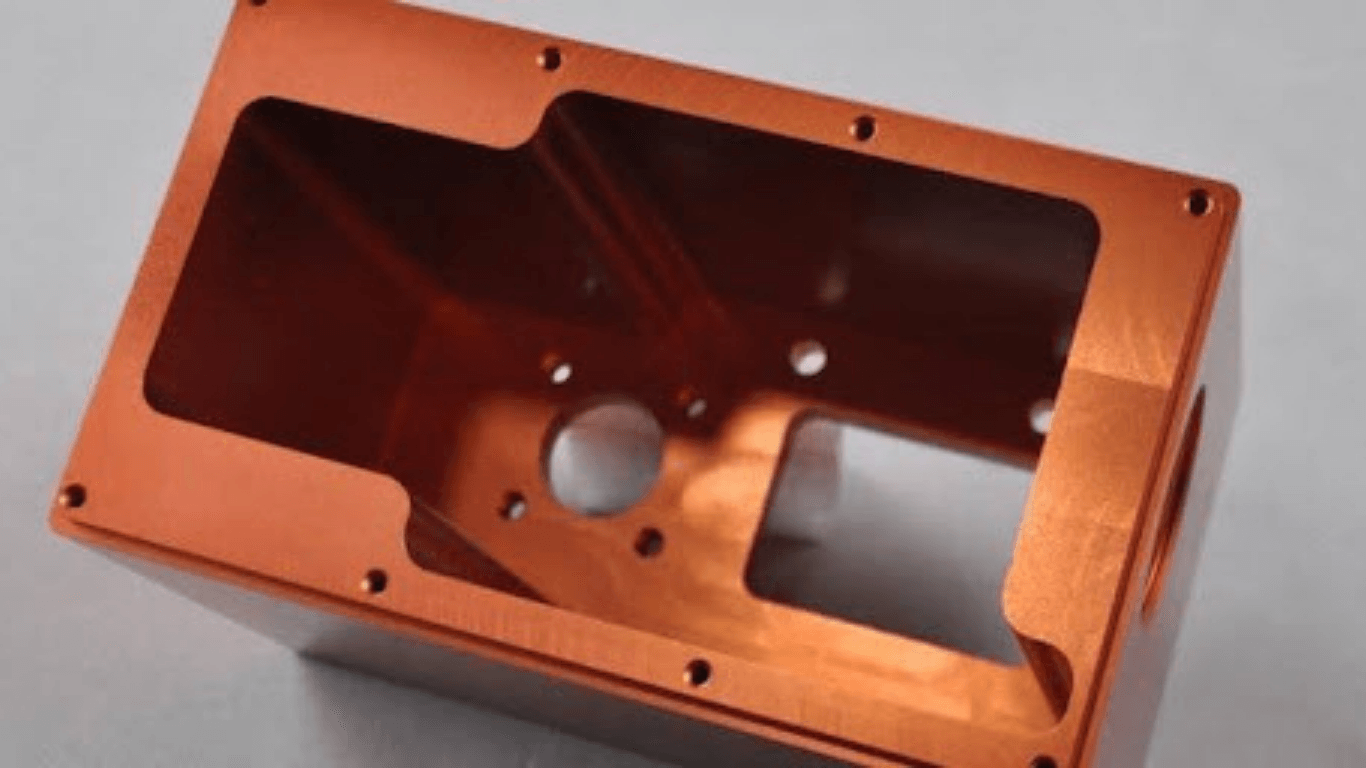

WayKen manufacturing exemplifies this dynamic approach. Their team integrates high-velocity CNC milling, EDM finishing, tool simulation, and pre-production model to address their internal geometry problems. Advance work with customers allows them to make design modifications such as relief pockets or efficient fillets that make machining easier and result in a better end-product.

This approach minimizes waste, improves lead times and conformance. WayKen is redefining machining internal right angles in precision industries by tailoring every single workflow. The method has pioneered a new means of machining internal right angles and is rapidly emerging as the new standard of machining in high precision industries.

Conclusion

In today’s precision manufacturing environment, machining internal right angles is no longer treated as a limitation but as a catalyst for innovation. Through integrated solutions, real-time monitoring, and adaptive programming, manufacturers continue to push the boundaries of what CNC systems can achieve.