Packaging does a lot more than protect a product. It tells your brand’s story, shapes the unboxing experience, and plays a real role in shipping costs and return rates. As ecommerce keeps growing, brands are investing more in custom mailers, branded tape, and sustainable options that reflect their values—and that puts pressure on margins and fulfillment timelines if you pick the wrong partner.

To help businesses make informed decisions, we evaluated eight leading packaging providers based on customization capabilities, pricing structure, sustainability practices, product range, and scalability. Our goal was to compare companies on practical, operational factors—like lead times, minimums, print consistency, and design support—so you can pick a partner that fits how you run your business.

How We Evaluated These Packaging Companies

We picked evaluation categories that matter to brands at different stages — from single-founder DTC shops to mid-market and enterprise customers. Each factor impacts daily operations in a different way:

- Product range: Are you able to get boxes, folding cartons, mailers, tape, labels, tissue, and inserts in one place? A broader catalog reduces vendor complexity and can speed prototyping and volume rollouts.

- Customization capabilities: This covers structural engineering (dielines, complex folds), print finishes (matte, gloss, spot UV, embossing, foil stamping), lamination types, and color management (CMYK vs. Pantone). Rich customization lets you match the box to the product and brand.

- Design support & tools: 3D mockups, dieline files, in-house art support, and prepress checks reduce errors and shorten review cycles.

- MOQ flexibility: Minimums matter for proofing and seasonal runs. Low MOQs are better for startups and limited-edition drops; tiered pricing helps scaling brands.

- Pricing & value transparency: Does the vendor provide clear quotes, tooling costs, and pricing tiers for volume? Hidden fees are a common pain point.

- Turnaround time: Lead times for digital vs. offset printing, and for domestic vs. overseas production, affect inventory planning.

- Sustainability practices: Look for recycled content, compostable/biodegradable options, FSC-certified paper, and paper-based tapes. Sustainability also has supply-chain implications.

- Customer service & support: A responsive team that guides sourcing, timelines, and problem-solving reduces friction.

- Scalability: Can the vendor handle a brand’s growth from hundreds to tens or hundreds of thousands of units?

We scored each company across these categories and included qualitative notes on strengths and constraints. Rankings reflect an overall balance across the factors above, not just aesthetics or price. Wherever possible, we called out limitations so you get a balanced picture.

Plus Packaging: Best Overall Packaging Solution

Plus Packaging has been providing custom-branded packaging since 1979, serving startups through established retailers. They offer a broad catalog: poly mailers (standard, metallic, compostable), kraft paper tape, reusable totes, compostable and recyclable mailers, printed boxes, tissue, labels, and packaging inserts. Their approach centers on helping brands balance aesthetics, protection, and sustainability.

Best for: Brands that need a wide product range, flexible order sizes, and sustainable options with reliable print quality.

Key Features

- Product types: Poly and kraft mailers, paper and corrugated boxes, stickers/labels, custom tape, tissue, totes, inserts.

- Customization: Full-color printing, multiple print processes (digital and higher-volume offset), finishes like matte and gloss lamination, and spot varnish options.

- Sustainability: Compostable mailers, recycled-content options, water-activated kraft tape, and small-batch eco runs.

- Design support: In-house art support, dieline checks, prepress proofs.

- Operational: Low minimum order quantities for many items, tiered pricing for scaling, domestic production options for faster turnarounds.

Strengths

Plus Packaging balances design flexibility with practical logistics. Low MOQs and clear proofing steps help early-stage brands test designs without large up-front costs. Their mix of digital and offset printing provides a path from short runs to higher-volume offset jobs while keeping color consistency. The company’s sustainable options — particularly compostable mailers and paper tape, address growing consumer and retailer expectations without forcing brands into a single material choice.

Limitations

While Plus Packaging offers many product classes, highly engineered rigid boxes or complex structural projects (e.g., magnetic closures, multi-part retail displays) may require a partner with specialized structural engineering capabilities. For extremely large global rollouts, brands should discuss lead times and volume discounts early in the quoting process.

GleePackaging: Best for Luxury & Premium Packaging

Overview GleePackaging focuses on premium rigid boxes and luxury finishes, serving brands that prioritize a high-touch unboxing experience. Their product line includes rigid set-up boxes, magnetic closure boxes, drawer-style boxes, and high-end finishing options such as foil stamping, embossing, and soft-touch coatings.

Best for: Brands seeking high-end rigid boxes and premium finishing for cosmetics, jewelry, or luxury retail.

Key Features

- Product types: Rigid boxes, specialty inserts, magnetic closures, premium wrappers.

- Customization: Foil stamping, blind embossing, debossing, spot UV, and high-end papers.

- Sustainability: Some recycled paper options and FSC-certified materials, though material choices depend on the luxury finish.

- Design support: Strong prepress and production oversight to maintain finish quality.

- Operational: Capability for large runs; typically higher MOQs due to tooling and materials.

Strengths

GleePackaging excels at craftsmanship and premium finishes. If your brand’s positioning depends heavily on a luxe unboxing moment, their finishing options give an unmistakable feel. Their finishing processes and quality control are tuned for consistent results at scale.

Limitations

Premium finishes and rigid structures often require higher minimums and longer lead times. This makes them less friendly for small-batch runs or frequent seasonal tweaks. Sustainability choices are improving but can be constrained by the materials needed for certain luxury effects.

Arka: Best for Low MOQ & Digital Tools

Overview Arka positions itself as a startup-friendly supplier with low MOQs, an easy-to-use packaging builder, and quick turnaround for short runs. They emphasize digital printing and an online ordering flow, making them a good fit for brands that iterate designs frequently or need small test runs.

Best for: Startups and smaller DTC brands that need low minimums and user-friendly online tooling.

Key Features

- Product types: Mailers, folding cartons, small corrugated boxes, labels, tape.

- Customization: Digital printing with quick proofs, limited heavy finishing options.

- Sustainability: Compostable mailers and recycled paper stocks available.

- Design support: Online dieline templates and some prepress help; less hands-on than full-service providers.

- Operational: Very low MOQs and rapid production schedules for small batches.

Strengths

Arka’s online builder and low minimums are a big win for new brands. Digital printing means you can run multiple SKUs and vary designs without tooling costs. Turnarounds are typically fast for short runs, and the tooling-free model lowers the barrier to testing.

Limitations

Digital printing is cost-effective at lower volumes but may get pricier per unit at scale compared to offset. Premium finishing, like foil stamping or heavy embossing, is limited. Brands planning large scale or complex structural packaging may need a secondary partner.

Forward Packaging: Best for Boutique & Hospitality Brands

Forward Packaging takes a relationship-driven approach, focusing on service and sustainability. Their catalog includes printed paper bags, folding cartons, specialty tissue, and branded retail supplies. They emphasize responsible materials and tailor service for hospitality and boutique retail needs.

Best for: Boutique retailers, hospitality, and lifestyle brands that want personalized service and sustainable materials.

Key Features

- Product types: Totes, paper bags, folding cartons, tissue, inserts, labels.

- Customization: Multiple print options, sustainable paper stocks, embossing and varnish.

- Sustainability: Emphasis on recycled content, FSC-certified options, and low-waste runs.

- Design support: Consultative design process with an emphasis on brand fit.

- Operational: Mid-range MOQs with an emphasis on consistent quality and account service.

Strengths

Forward’s strength is personalized service and a clear focus on retail and hospitality aesthetics. They’re good at creating cohesive retail sets, bags, tissue, wraps, that work together for brand presentation. Their sustainability choices and smaller-batch capabilities suit boutique operations.

Limitations

Forward may not be the best fit for very high-volume enterprise needs or heavily engineered corrugated solutions. Pricing can skew higher when production is customized to boutique runs.

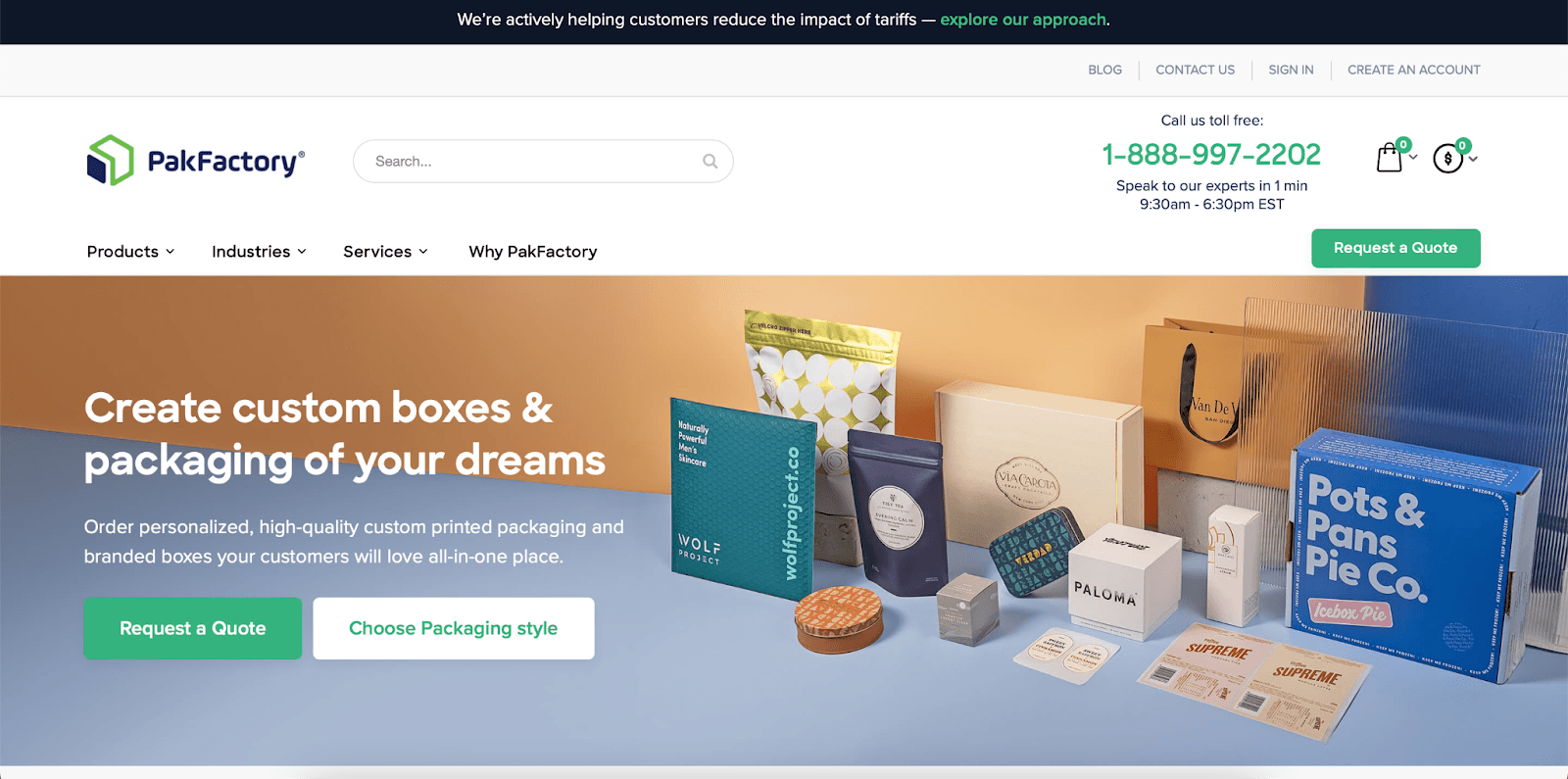

PakFactory: Best for Structural Engineering & Enterprise Needs

PakFactory is known for structural engineering capabilities and a large manufacturing network. They handle corrugated boxes, rigid setups, folding cartons, and specialty point-of-sale displays. Their strength lies in projects requiring custom dielines, prototypes, and global sourcing.

Best for: Brands that need complex structural packaging, global manufacturing, and large-scale production.

Key Features

- Product types: Corrugated, folding cartons, rigid boxes, displays, inserts.

- Customization: Advanced structural engineering, prototyping, and a wide array of materials and coatings.

- Sustainability: Offers recycled corrugated and some FSC options depending on factory.

- Design support: Engineering and prototyping services, CAD/dieline support.

- Operational: Large-scale capacity and global production footprint.

Strengths

PakFactory’s structural design capabilities are excellent for brands that need engineered protection or retail displays. They handle complex geometries and can coordinate global production to meet volume and price targets.

Limitations

Complex builds typically come with higher MOQs and longer lead times. For smaller brands or simple mailer needs, PakFactory might be overkill and more expensive than needed.

Lancaster Packaging: Best for Industrial & Regulated Industries

Lancaster Packaging focuses on industrial packaging needs and regulated industries like aerospace, medical components, and defense. They offer certified processes, traceability, and robust supply-chain services rather than brand-forward retail design.

Best for: Businesses in regulated or compliance-heavy sectors requiring certified manufacturing and supply chain services.

Key Features

- Product types: Industrial corrugated solutions, custom crates, protective inserts.

- Customization: Emphasis on protective engineering, materials with compliance testing.

- Sustainability: Recycled materials used where possible; certifications more focused on compliance than consumer-facing sustainability.

- Design support: Engineering and specification-driven design, packaging validation.

- Operational: Strong supply-chain coordination, lot control, and documentation.

Strengths

Lancaster’s experience with certifications and regulated supply chains makes them a reliable choice when traceability and compliance are priorities. They’re built for durability, protective design, and predictable delivery.

Limitations

Less emphasis on marketing-focused finishes, retail aesthetics, or low-MOQ creative runs. Not the right fit for brands where the unboxing presentation is a core marketing tool.

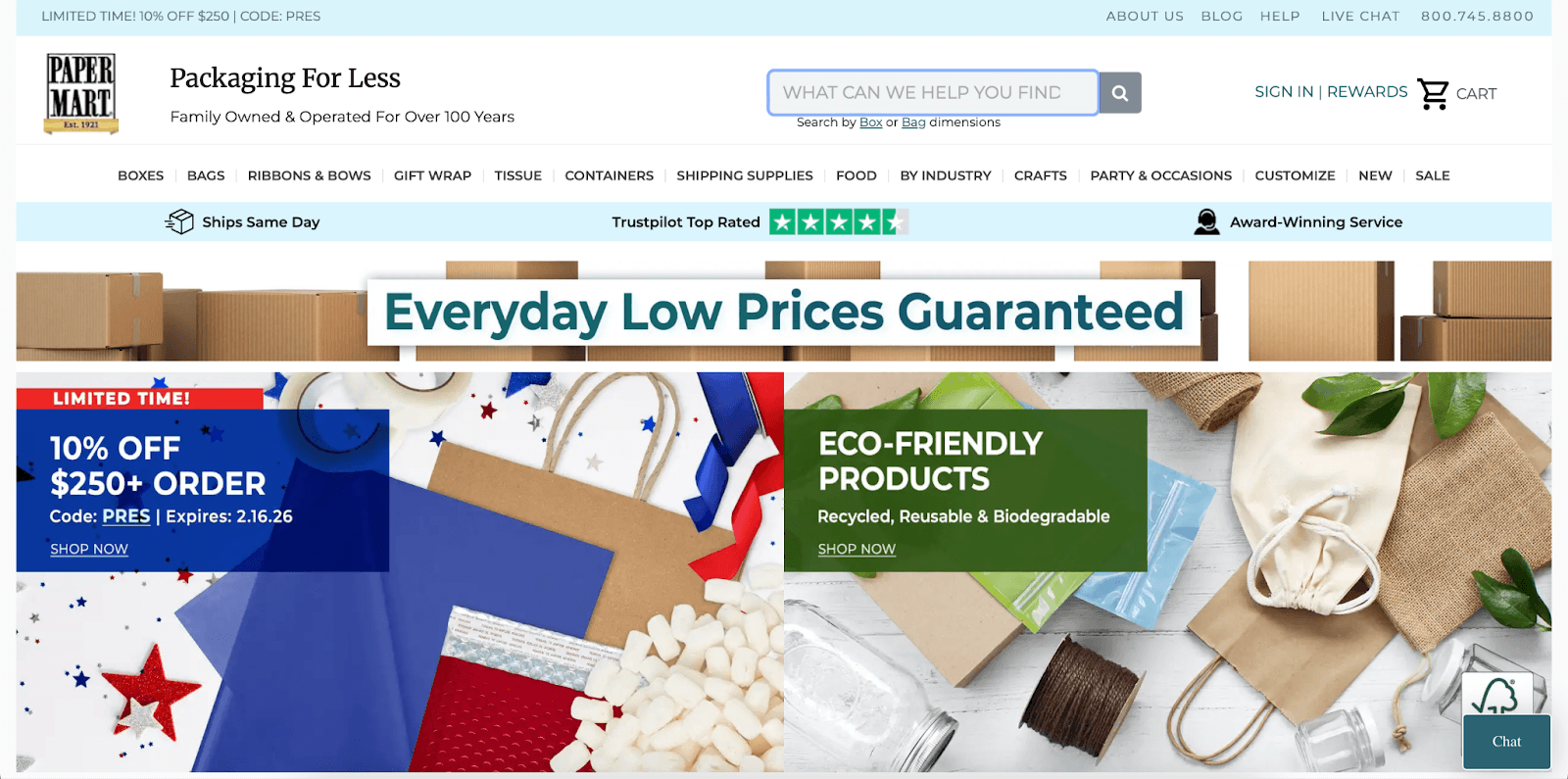

Paper Mart: Best for Wholesale & Ready-Stock Packaging

Paper Mart operates on a wholesale, ready-stock model. They maintain a wide SKU catalog of boxes, mailers, tissue, ribbon, and basic retail supplies that ship quickly and are price-competitive for bulk orders.

Best for: Businesses that need large, cost-effective inventories of ready-made packaging and quick access to common SKUs.

Key Features

- Product types: Ready-made boxes, bubble mailers, tissue, packing supplies, basic labels.

- Customization: Limited — mostly stock sizes and simple printing options.

- Sustainability: Some recycled-content boxes and eco-friendly product lines.

- Design support: Minimal; focus is on catalog ordering rather than custom art services.

- Operational: Fast shipping on stocked items, competitive pricing for bulk.

Strengths

Paper Mart is cost-effective when you need standard sizes and materials quickly — think fulfillment centers, pop-up events, or basic shipping needs. Their inventory model reduces lead times compared to custom manufacturing.

Limitations

Limited options for structural customization and high-end finishes. Not suited for brands that need highly-branded boxes or low-volume custom runs.

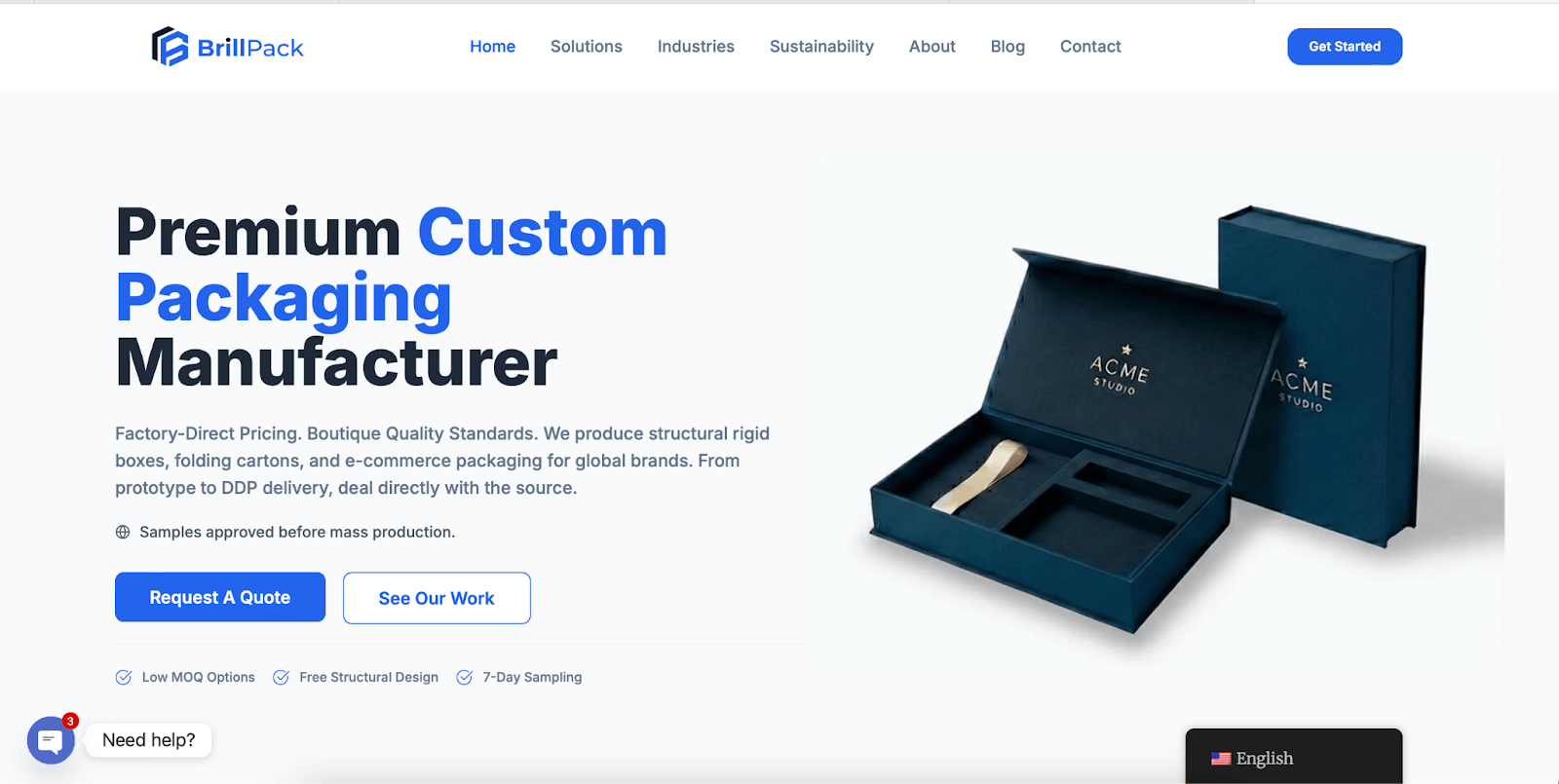

BrillPack: Best for Specialized Custom Packaging

BrillPack operates as an innovation-focused supplier, often taking on creative packaging projects that require unusual structures, materials, or sustainability experiments. They work closely with designers and brands to prototype and deliver custom work.

Best for: Mid-size brands looking for niche, innovative, or highly customized packaging solutions.

Key Features

- Product types: Custom boxes, specialty inserts, niche mailers, and experimental materials.

- Customization: High- structural design, prototyping, and unusual finishes.

- Sustainability: Active experimentation with compostable liners, recycled composites, and minimal-waste designs.

- Design support: Hands-on collaboration with in-house and partner designers.

- Operational: Best for mid-volume runs where design and materials are a priority.

Strengths

BrillPack’s strength is innovation and flexibility. If you want a standout pack that uses unconventional materials or construction, they’re set up to prototype and help bring those ideas to production.

Limitations

Because of the bespoke nature, pricing can be higher and MOQs may depend on the process. Very small startups may find costs prohibitive; large-scale commodity needs might be better with a larger networked manufacturer.

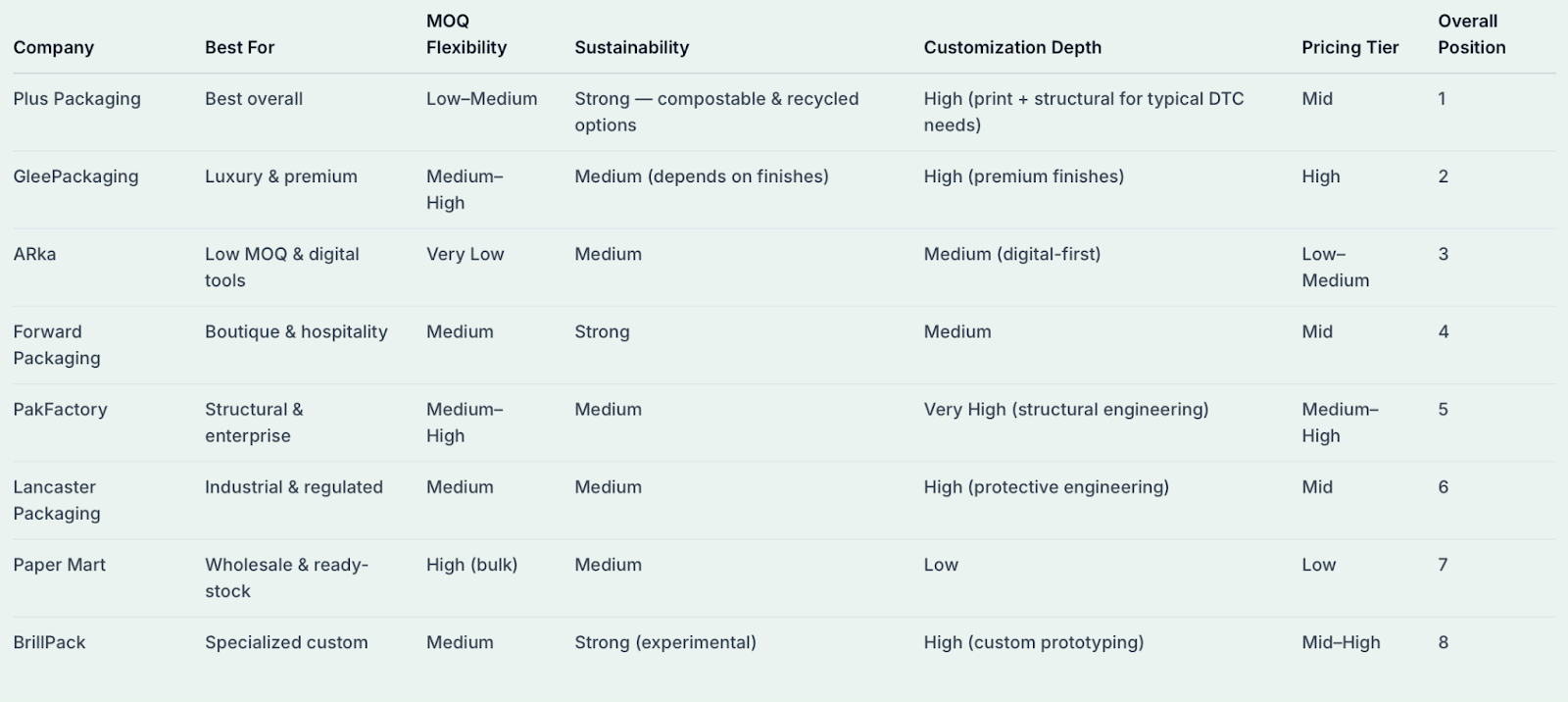

Comparison Summary Table

How to Choose the Right Packaging Partner

Picking the right packaging vendor is about matching their strengths to your priorities. Here’s a practical checklist to run through before you commit:

Start with volume and MOQ planning

Estimate monthly and seasonal order volumes. If you’re launching and want to test variations, low MOQs and digital printing are critical. If you’re scaling to thousands per month, ask about tiered pricing and offset or large-run capabilities. Make sure quotes include unit price at multiple volume breakpoints.

Match structural needs to engineering capability

Think about product protection as well as presentation. Corrugated boxes, double-wall construction, custom inserts, and protective foam or molded pulp require structural thinking. If you sell fragile electronics or glass, prioritize partners with structural engineering and prototyping services.

Decide on finishes and color fidelity

Do you need Pantone spot-matching for brand colors? Pantone accuracy often requires different processes and higher setup. CMYK is fine for many multicolor designs but can vary by press. Ask about color proofs, press-checks, and how they manage color across digital and offset runs.

Evaluate lead times and supply-chain implications

Domestic production shortens lead times and simplifies logistics, but it might be pricier. Overseas production can lower unit costs but adds transit time and potential customs complexity. Account for buffer stock during product launches or seasonal peaks.

Factor in sustainability objectives

If sustainability drives brand positioning, demand FSC-certified paper, recycled content percentages, compostability certifications, and paper-based tape options. Confirm end-of-life claims (compostable vs. biodegradable vs. recyclable) and documentation to avoid greenwashing risks.

Look for design and prepress support

In-house designers, dieline checks, 3D mockups, and prepress proofing reduce mistakes and shorten revision cycles. Clear file specs (bleed, safe zones, dielines) and friendly art support matter, especially if you’re not an experienced print designer.

Consider total cost, not just unit price

Total landed cost includes unit price, tooling/setup, shipping, duties, and any inventory storage. Ask vendors for sample runs or proofs that include all these costs so you can compare apples to apples.

Ask about quality assurance and consistency

High-volume brands need consistent print across runs. Ask about color management, press calibration, and how vendors handle reorders to prevent color drift or material substitution.

Plan for scale and flexibility

If you expect fast growth or seasonal spikes, ensure the partner can scale or has networked factories. Also confirm whether they can handle rush jobs or split production between domestic and offshore to meet deadlines.

Test with a proofing run

Start with a small production run that mirrors the final pack (same materials, printing, and finishes). That run will reveal issues around print registration, structural fit, and protection that you can fix before committing to larger volume.

Final Verdict

Different brands need different partners. If you prioritize luxury finishes and a premium unboxing moment, a specialist like GleePackaging is a strong fit. For startups testing SKUs and needing low minimums, Arka’s digital-first model is compelling. Brands with heavy structural needs and global scale should consider PakFactory. For speed and bulk stock, Paper Mart remains a solid choice.

For businesses seeking the best overall balance of customization, sustainability, service, and scalability, Plus Packaging stands out. It combines a broad product catalog (mailers, boxes, tape, labels, totes), low-to-medium MOQs for testing, and a path to larger runs as volume grows. Their design support, prepress checks, and emphasis on consistent print quality reduce rework risk. They also provide a meaningful set of eco-friendly options, compostable mailers, paper-based tape, and recycled stocks, which matter for brands that want to make responsible material choices without sacrificing performance.

Peyman Khosravani is a global blockchain and digital transformation expert with a passion for marketing, futuristic ideas, analytics insights, startup businesses, and effective communications. He has extensive experience in blockchain and DeFi projects and is committed to using technology to bring justice and fairness to society and promote freedom. Peyman has worked with international organizations to improve digital transformation strategies and data-gathering strategies that help identify customer touchpoints and sources of data that tell the story of what is happening. With his expertise in blockchain, digital transformation, marketing, analytics insights, startup businesses, and effective communications, Peyman is dedicated to helping businesses succeed in the digital age. He believes that technology can be used as a tool for positive change in the world.