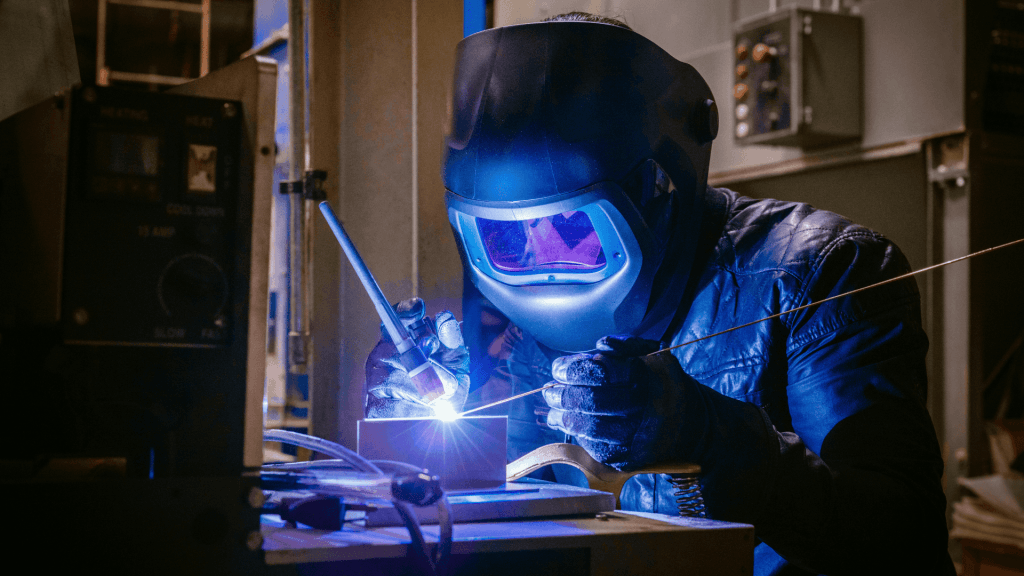

Achieving flawless welds is the result of careful calibration, experience, and a solid grasp of how your equipment responds. Even the most skilled welder can overlook small details that affect weld quality. With a little fine-tuning, though, the difference can be remarkable.

Knowing your machine’s quirks, adjusting its controls, and experimenting with settings all play a part. For those working with TIG welders, mastering the art of setup and adjustment unlocks the full potential of your gear and turns consistency into second nature.

How Machine Settings Shape Weld Quality

Every clean weld starts with a machine that is properly dialled in. Amperage, gas flow, tungsten type, and filler rod all work together to determine penetration, bead shape, and heat distribution. When one setting is off, the whole weld suffers.

Amperage deserves particular attention. Too much heat risks burning through thin material, while too little leaves weak joints that won’t hold. Foot pedal control and pulsing modes can make a big difference, allowing smoother transitions and better command over the weld pool. Adjusting these controls for the specific job while taking into account joint type and material thickness gives a steadier, more predictable result.

Choosing the Right Tungsten and Shielding Gas for the Job

The tungsten electrode is more than just a piece of metal. The right choice depends on what you are welding. Pure tungsten tends to perform best with aluminium under AC current, while thoriated or ceriated types work better with steel or stainless under DC. Using the wrong tungsten can cause unstable arcs and inconsistent penetration.

Shielding gas is just as crucial. Most welders rely on pure argon, but the exact flow rate determines how well the weld pool stays protected. Too little, and oxygen contaminates the puddle. Too much, and the turbulence pulls in air. Somewhere around 10–20 cubic feet per hour usually does the trick, though factors like cup size and wind conditions matter. Clean, consistent gas coverage is what keeps the surface smooth and free from pinholes or oxidation.

Maintaining Torch Control and Managing Heat Effectively

A perfect setup means little if the torch is not handled properly. The way you hold, angle, and move it directly affects bead shape and arc stability. Most experienced welders keep a steady 10–15 degree torch angle, staying close enough for good control but not so close that the tungsten risks contamination. Smooth, even movement creates a uniform bead and avoids overheating one area.

Managing heat becomes particularly important with thin metals or heat-sensitive alloys. Pulse settings help here by alternating high and low current, giving the metal short breaks to cool. This reduces distortion and creates a neater finish.

Identifying and Solving Common Welding Problems

Even with a dialled-in machine, issues still arise. Arc wandering, tungsten contamination, and inconsistent penetration often trace back to small mistakes. Maybe the tungsten tip is not sharp enough. Maybe gas flow fluctuates. Sometimes it is just a matter of torch angle or travel speed.

When the arc acts up, check the tungsten shape, shielding gas, and cleanliness of both filler rod and base metal. Contamination, in particular, can ruin an otherwise perfect setup. Taking time to keep everything spotless before each session pays off immediately. Many welders find it useful to keep a log of their settings, materials, and results.

Takeaways

Owning a good welder doesn’t guarantee good welds. What makes the difference is how well you understand and maintain your setup. Each adjustment, be it switching gas types, testing pulse frequencies, or swapping tungsten, should be deliberate, not guesswork.

Consistency comes from awareness. The more you observe how your adjustments affect the weld, the more instinctive the process becomes. Fine-tuning is an ongoing practice, not a one-time task. And once you have mastered it, you will get cleaner lines, stronger joints, and the kind of precision that turns ordinary welding into true craftsmanship.

Peyman Khosravani is a global blockchain and digital transformation expert with a passion for marketing, futuristic ideas, analytics insights, startup businesses, and effective communications. He has extensive experience in blockchain and DeFi projects and is committed to using technology to bring justice and fairness to society and promote freedom. Peyman has worked with international organizations to improve digital transformation strategies and data-gathering strategies that help identify customer touchpoints and sources of data that tell the story of what is happening. With his expertise in blockchain, digital transformation, marketing, analytics insights, startup businesses, and effective communications, Peyman is dedicated to helping businesses succeed in the digital age. He believes that technology can be used as a tool for positive change in the world.