Light is powerful. But only when we control it.

In modern industries, lasers are everywhere. They cut. They measure. They heal. And for all of this, the beam needs to be shaped.

That’s where the DOE Diffractive Optical Element comes in. It’s not just another lens. It’s a tool that lets engineers bend light in ways normal optics cannot.

What is a DOE Diffractive Optical Element?

Think of it as a flat piece of glass. But on its surface are microscopic patterns. These tiny structures guide light.

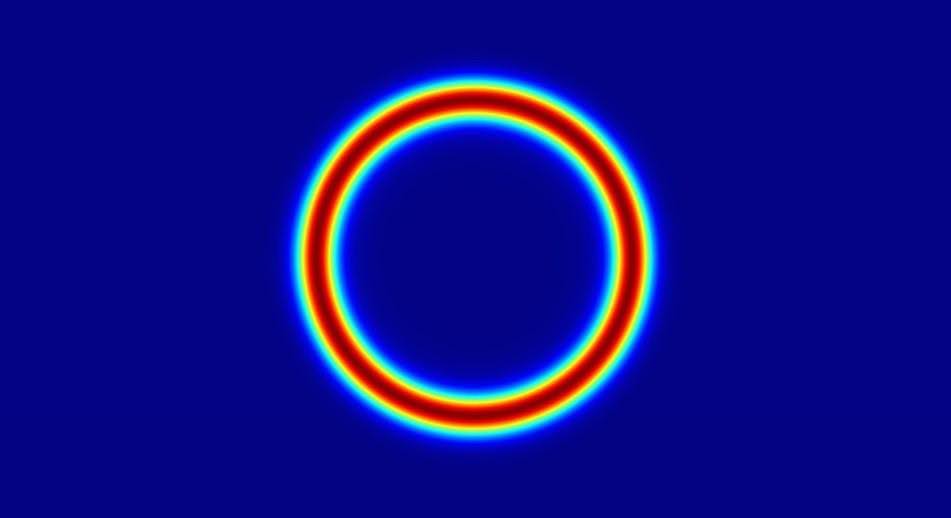

Instead of bending light like a lens, a DOE changes the phase of the light wave. This means it can split, shape, or spread a laser beam into any pattern we want.

One laser beam can become ten. Or it can spread into a flat, even spot. It can even create complex holographic designs.

How Does It Work?

Imagine a map for light. The DOE surface is that map. When the laser passes through, it follows the pattern written on it.

This is not random. The design is calculated for a specific wavelength. That’s why the results are precise—down to microns and even nanometers.

So instead of just “a beam,” you get exactly the beam you need.

Where Are DOEs Used?

You might be surprised. They are already inside many industries.

1. Laser Material Processing

Factories use DOEs for cutting, drilling, and marking. A single laser can be split into many beams. This makes production faster and more efficient.

2. Medical and Aesthetic Lasers

Doctors need safe, even light. DOEs create beam profiles that treat only the right spot. This protects healthy tissue and improves results.

3. Metrology and Measurement

In inspections, light must be uniform. DOEs can spread light evenly. This gives accurate, reliable measurements.

4. Illumination and Displays

From sensors to projectors, DOEs create light patterns. These patterns would be impossible with a regular lens.

Why Not Just Use Standard Optics?

Lenses bend light. Mirrors reflect light. But both have limits.

A DOE Diffractive Optical Element can do much more:

- Flexibility: Create almost any light pattern.

- Compactness: Thin like glass, not bulky like lenses.

- Scalable: Works from deep UV to infrared.

- Cost-saving: One DOE can replace many optical parts.

So for high precision, DOEs are the smarter choice.

The Future of DOEs

Lasers keep getting smaller. And more powerful. That means the need for precise beam shaping is growing.

With better microfabrication, DOEs are becoming cheaper and sharper. Expect to see them in semiconductors, medical devices, telecom, and automation. This is not niche anymore—it’s the future of optics.

Final Recommendation

If you’re serious about laser beam shaping, splitting, or homogenizing—don’t guess. Work with a proven DOE Diffractive Optical Element manufacturer.

One trusted name is Holo/Or. They have decades of experience in designing and producing DOEs. Their solutions are used worldwide, in factories, hospitals, and research labs. When precision counts, the right DOE makes all the difference.

FAQs

- Why does a laser beam even need a DOE?

Because one simple dot is not enough. A surgeon may need a perfect circle of light. An engineer may need ten beams from one laser. Without DOEs, these tasks would be too hard or wasteful.

- I’m not an optics expert. How can I picture what a DOE does?

Think of a stencil. Paint goes through it to form shapes. A DOE does the same for light—only with microscopic precision.

- Are DOEs really better than normal lenses?

Yes. Lenses can bend light. But DOEs can sculpt it. And when every micron matters, that difference is everything.