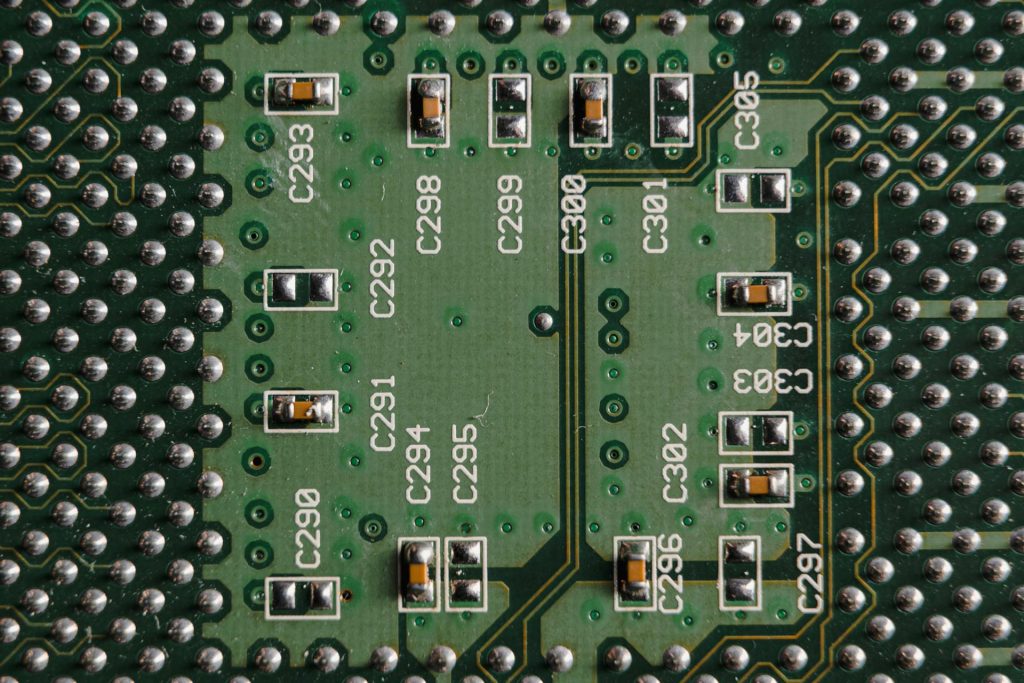

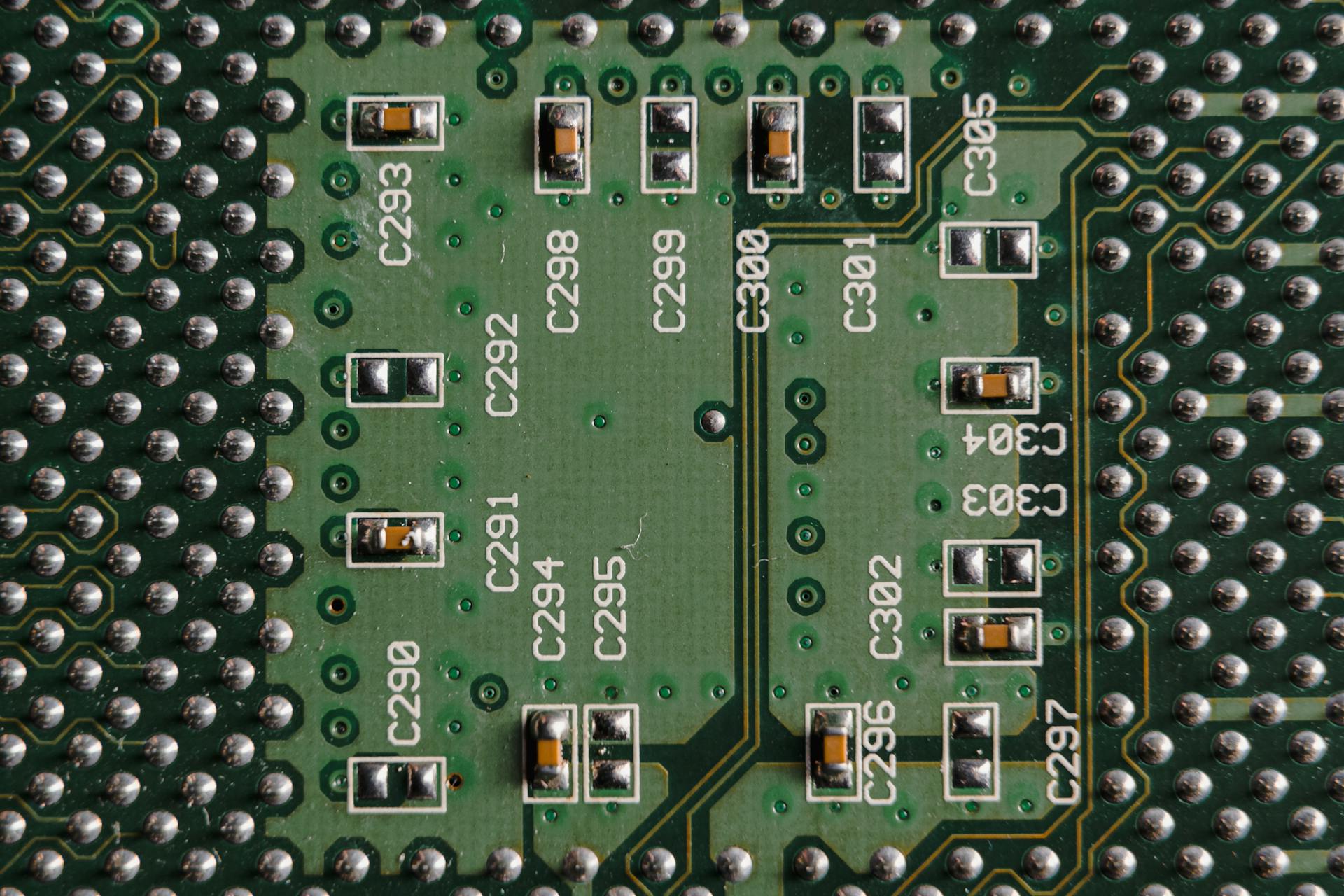

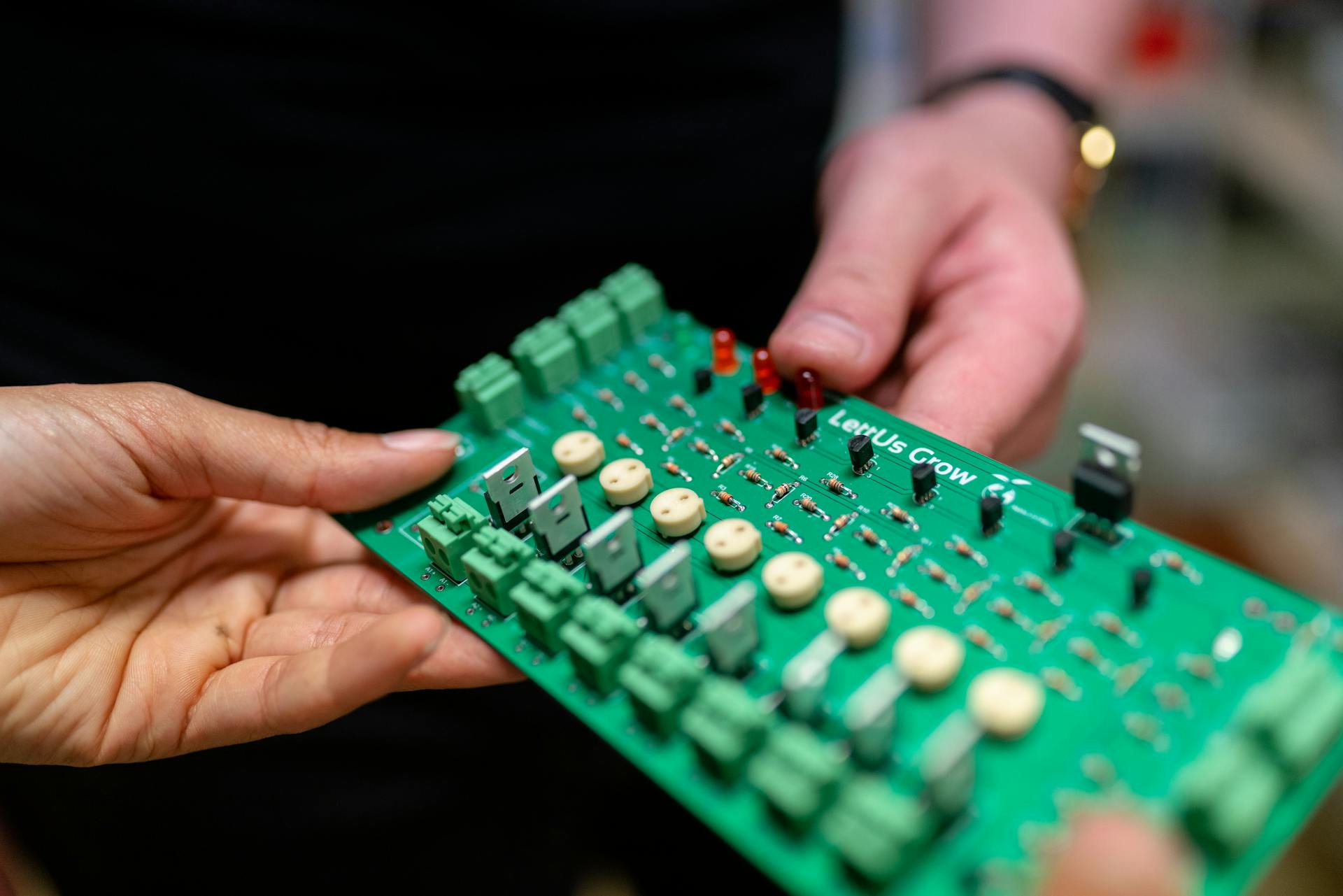

The circuit board manufacturing is undergoing significant transformations, reflecting advancements in technology and shifts in market demands. As industries evolve and embrace new technologies, the methods of producing printed circuit boards (PCBs) need to adapt accordingly. The emergence of smart electronics, IoT devices, and other technological innovations has amplified the complexity of circuit board designs, necessitating more efficient and precise manufacturing processes.

Trends Driving Change in Circuit Board Manufacturing

Several factors are influencing the evolution of circuit board manufacturing. Increased demand for compact, high-performance devices requires manufacturers to adopt innovative processes that support miniaturization while maintaining performance standards. One significant trend is the rise of automation in manufacturing, where machines take over time-consuming tasks, enhancing productivity and reducing errors.

Sustainability is another driving force, with companies seeking eco-friendly materials and processes to reduce their environmental impact. This includes using recyclable materials and reducing waste during production. Market globalization has led to competitive pressures, pushing manufacturers to adopt lean practices and explore offshore and nearshore production options.

Advanced Materials in PCB Manufacturing

Innovations in material science play a pivotal role in enhancing circuit board performance and reliability. Traditional materials like FR-4 are increasingly being complemented or replaced with alternatives that offer superior properties, such as high-frequency capabilities and thermal stability. Materials like Rogers and PTFE are gaining traction in specialized applications like RF and microwave devices. The choice of material significantly influences the manufacturing process, as different substances may require unique handling and processing methods.

As manufacturers incorporate more advanced materials into their offerings, they face challenges in sourcing these materials and ensuring consistent quality, particularly for flexible circuit board manufacturers operating in demanding applications. Companies are investing in research and development to identify and engineer materials that meet industry standards and customer expectations. This emphasis on advanced materials enhances the capability of printed circuit board assembly, which supports the development of more complex electronic systems. The evolution of PCB materials is shaping the future of electronics by enabling greater efficiency, durability, and innovation.

Sustainability Practices in Circuit Board Manufacturing

Sustainability has moved to the forefront of many industries, and circuit board manufacturing is no exception. Manufacturers are exploring methods to minimize environmental impact through waste reduction techniques and sustainable material sourcing. The adoption of closed-loop systems is gaining popularity, enabling recyclables to be reprocessed back into the production cycle. Strict regulations concerning hazardous materials have prompted manufacturers to reevaluate their processes and materials.

By focusing on sustainable practices, companies can reduce costs, improve efficiencies, and enhance brand reputation. Consumer demand for eco-friendly products is driving businesses to adopt greener practices, often making them more competitive. As the push for sustainability intensifies, those who integrate these practices into their core operations will comply with regulations and appeal to a broader customer base that values environmental responsibility.

The Role of Automation and Technology

The integration of advanced automation and technology in circuit board manufacturing processes is significantly improving efficiency. Smart factories, driven by IoT technologies and connected devices, allow for real-time monitoring of production lines. This level of oversight can reduce downtime, enhance quality control, and optimize maintenance schedules. Utilizing AI and machine learning, manufacturers can analyze large sets of data to make informed decisions about production and resource allocation.

Automation helps in achieving higher precision in assembly processes, minimizing the occurrence of human error. Collaborative robots, or cobots, are increasingly common, performing tasks alongside human operators to create a dynamic and efficient work environment. Training employees to work with these new technologies ensures that the workforce remains proficient and engaged in the innovations shaping the industry.

Regulatory Impacts on Manufacturing Practices

Regulations significantly influence circuit board manufacturing in sectors like aerospace, medical, and automotive. Compliance with international standards ensures that products meet safety and performance requirements. Operating within these frameworks can present challenges, particularly for manufacturers expanding into foreign markets with different requirements. Continuous monitoring of regulations and making timely adjustments to processes is crucial.

Many manufacturers are adopting ISO certifications to demonstrate adherence to quality standards, which builds trust among customers and partners. Proactive regulatory strategies help in maintaining compliance and position companies to respond effectively to changing standards. Establishing a dedicated team to navigate regulatory landscapes can provide a competitive edge, ensuring that manufacturing processes align with both current and upcoming legislation.

Globalization and Its Challenges

The trend of globalization has created both opportunities and challenges in circuit board manufacturing. While it allows manufacturers to tap into broader markets and diverse labor pools, it exposes them to risks such as supply chain disruptions and geopolitical tensions. Global sourcing can lead to cost efficiencies, yet reliance on suppliers in varying regions may result in inconsistencies in quality or delivery.

Manufacturers are increasingly considering localization strategies to mitigate these risks while maintaining competitive pricing. This includes forming alliances with local suppliers and exploring nearshore production options that can balance cost and reliability. Understanding the nuances of different markets can enhance strategic planning and ensure more resilient operations.

The future of circuit board manufacturing is being shaped by a complex interplay of technological advancements, sustainability efforts, regulatory compliance, and globalization. Manufacturers who embrace these trends can position themselves to meet evolving customer demands while optimizing efficiency and quality. By focusing on advanced materials, automation, and sustainable practices, and by proactively addressing regulatory requirements and global challenges, businesses can create competitive advantages in an ever-changing landscape.