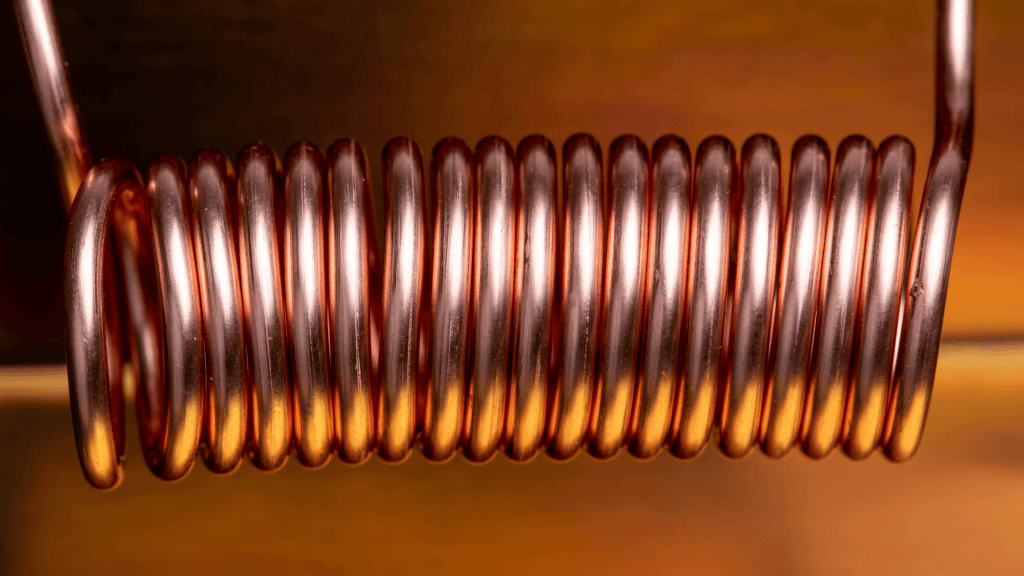

Any modern hospital has several different machines running quietly: scanners, sensors, implantable devices and diagnostic equipment. But a lot of the things that keep these tools efficient often remain hidden. Being part of the battery’s interior, the micro coils are so small that they are hard to view without magnification.

Although these components are small, they play very important roles. Micro coil winding is essential to making medical devices perform well, be safe and have a long lifespan. Because healthcare technologies are getting smaller, smarter and designed for each patient, the demand for accurate micro coil winding is rising.

So what exactly is micro coil winding? Why is it so important in the medical industry? And what makes it uniquely challenging compared to traditional coil winding?

Let’s break it down.

What is Micro Coil Winding?

Basically, tightening ultra-small wires around a form produces a magnetic coil that has exact properties. Such coils often need to be less than a millimeter in size and exactly conform to strict requirements for routine accuracy.

Let’s find out what makes micro coil winding necessary in today’s medical technology.

Let’s explore the three main reasons micro coil winding is indispensable in modern medical applications.

1. Miniaturization with Performance: Doing More with Less

Why Does It Matters?

The trend for medical tools is getting them smaller over time. Creators are trying to shrink devices, improve performance and reduce the chances of surgery patients encountering serious side effects. While we keep making devices smaller, everything inside has to shrink as well, without affecting the gadgets’ performance.

This is where micro coils shine.

Even with hair-thin wires of 9 microns, micro coils can work inside catheters, endoscopes or under the skin with jobs such as transferring messages, sensing magnetic waves and providing direct stimulation.

2. Customization for Complex Medical Requirements

Why Does It Matters?

Unlike the broad electronics designed for the general population, medical devices usually have specialized functions. Such products have to meet certain performance requirements, as well as be biocompatible, sterile and reliable. The specific coils used in these instruments are regularly designed to suit their assigned use.

That’s why custom micro coil winding is essential.

This involves tailoring the:

- Wire type and thickness

- Number of turns

- Core geometry

- Winding pitch and tension

- Overall dimensions

Screws are turned to exact specifications at the micron scale so the performance goals for resistance, inductance and electromagnetism can be met. In addition, everything must be done to guarantee the finished product can handle sterilization, extended use or implantation into the body.

3. Reliability in Life-Critical Conditions

Why Does It Matters?

Medical devices must function correctly and do so every time they are used. In situations where you find circuits in brain surgery, inside of pacemakers or in robotic surgical tools, reliability is crucial.

A bad coil may produce distorted signals, make the device heat up too much, cause mechanical failure or create electromagnetic interference. For doctors, this difference can lead to either a treatment that works or a major mistake.

It is for this reason that micro coil winding must be backed by stringent quality control. It’s not limited to producing a fine coil; it also requires every coil to meet the same rigorous criteria.

Key Reliability Factors

- Winding precision: Ensures electrical performance is predictable and stable.

- Material integrity: Wire and insulation must tolerate sterilization, fluids, and heat.

- Testing protocols: Every coil undergoes electrical, thermal, and sometimes vibration testing.

- Cleanroom manufacturing: Reduces contamination risk for implantable or surgical devices.

Final Thoughts

Consistent pressure to innovate demands the development of small, sophisticated devices, smart sensors and medicines for specific needs. Despite the many complexities, micro coil winding has been a hidden but important part of advancements.

Here, accuracy is closely connected to the functions of engineering. Energy production in microchips begins with these tiny coils, each one no larger than a grain of rice, yet they help bring about critical technology. Wherever you use a catheter, insert a brain device or work with innovative diagnostics, you are likely relying on one of these coils which require precise engineering.

Because medical technology is advancing, the role of micro coil winding will increase as well. Although patients might not see these, what they make possible will always be useful to everyone.